The renewable energy sector has seen massive growth in the last several years. Solar projects are becoming more common as solar energy becomes economically viable across the globe — the 21% increase in year over year growth in the United States in 2019 is indicative of PV’s increasing competitiveness. All that growth means that new farms are coming online every day. Newly constructed solar farms are required to complete a commissioning inspection to ensure that the site is operating properly. This process presents several opportunities for asset owners to incorporate aerial inspection into their maintenance procedure during the early stages of operation, helping to maximize ROI from a solar site throughout its entire life span.

Commissioning inspections are performed to verify that a system meets the asset owner’s performance and safety standards. The process typically includes ensuring that all hardware has been properly installed, checking that the system is functional and safe, and measuring performance benchmarks. Commissioning can be a time and labor-intensive process — technicians are required to spend hours in the field performing visual inspections on foot, often inspecting only a small sample of a site’s modules. Inspecting modules manually is therefore expensive and inaccurate.

Aerial inspection eliminates the shortcomings of traditional field walks. Using a drone equipped with thermal imaging systems, pilots are able to capture performance data on every individual module. Conducting inspections aerially is also nearly 4X faster than manual inspection. Furthermore, capturing module data aerially identifies defects more accurately and consistently. With a comprehensive aerial inspection, technicians are freed up to perform other high-skill tasks.

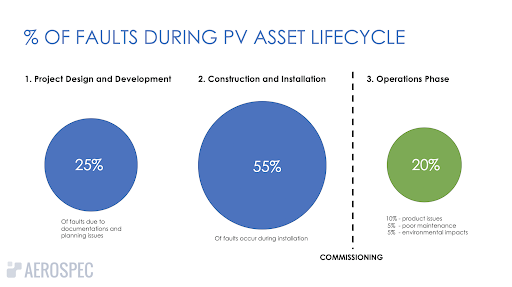

The value of aerial inspection when commissioning PV systems is substantial. A report from TUV Rheinland found that 80 percent of module defects occur prior to operation, 25 percent of which are found during the planning phase and 55 percent of which happen during construction and installation (see Figure 2). From a sample of aerial commissioning inspections spanning over 450MW of newly constructed solar sites, Aerospec Technologies has found that roughly 13.4 percent of modules are either shipped with defects from the manufacturer or damage from construction processes. With traditional methods of taking a sample size to conduct IV curve tracing, identifying all malfunctioning panels is nearly impossible. When left undiscovered into day-to-day operations, performance benchmarks taken during commissioning are inaccurate, and the system will operate below maximum efficiency from day one.

According to Zip Recruiter, solar technicians are paid $25/hour on average. Working 8 hours per day, it would take 2 technicians approximately 30 days to inspect every module on a 100MW site, costing roughly $12,000. Compared to manual inspections, aerial inspection costs a fraction of the price, is nearly 10x faster, and provides more accurate results.

Incorporating aerial inspection into a commissioning process gives asset owners more confidence in their investment. They are able to get a complete picture of site performance and act proactively when anomalies occur. For defective modules system operators are able to immediately identify defects and invoke the manufacturer’s warranty before it expires, ensuring that the system is generating the maximum yield and owners are getting the full value of the panels they paid for from the commercial operation date.

Commissioning inspections are just one opportunity to incorporate aerial inspection into a solar site’s regular maintenance and inspection procedures. In addition to their value in verifying that a newly commissioned site is operating properly, commissioning inspections continue to provide valuable insight throughout a system’s operating life. When implemented regularly, aerial inspections increase yield and lower O&M costs by ensuring that every module is operating at maximum efficiency. Using aerial inspection during the commissioning process gives a more complete picture of performance prior to operation and provides asset owners the opportunity to reap the benefits of an optimized yield for the entire duration of operations.

With commissioning inspections — as with routine O&M inspections — time is money in solar. The longer it takes to receive inspection results, the longer it will be before module anomalies are corrected, and the more revenues will be lost from electricity left ungenerated. For example, one of Aerospec’s clients that was in the process of commissioning a 250MW solar farm was at risk of losing $97,000 per day on project delays. Aerospec Technologies’s industry leading AI allows us to get managers vital deliverables within hours rather than waiting for days or weeks.

If you are interested in learning more about how aerial inspection can aid in your commissioning inspection, please contact us at www.aerospec.us for more information or to schedule a demo today.