Between flooding, gale force winds, lightning, and hail, extreme weather is the number one cause of PV insurance claims, accounting for roughly 50% of the total. It is therefore critical for operations and maintenance (O&M) teams to deploy immediately on site afterwards, and the speed and flexibility of aerial inspection allows operators to quickly get their portfolios back online in the aftermath of a disaster.

The greatest strength of aerial inspection when used in an emergency response is its turnaround time. Aerospec Technologies is the industry leader in turnaround time and is able to generate a comprehensive report complete with visual aids and geo-tagged data for farms up to 50MW within 72 hours. In emergency situations, smaller segments of reports for areas that require urgent attention can be generated within hours. O&M providers will find rapid report generation to be an invaluable tool when combating damage caused by extreme weather. The ability to rapidly receive and act on inspection data can be the difference between quickly getting a system back online and hundreds of thousands of dollars worth of lost revenue.

Although the complete destruction of modules is largely preventable through proper installation and maintenance, extreme weather also causes damage that is harder to see. PVEL reports that in instances where fewer than 5% of panels were visibly damaged by hail or high winds, they discovered that up to 100% of modules exhibited micro-cracking. Global Sustainable Energy Solutions estimates a loss of approximately 2.5% in modules where micro-cracks do not isolate parts of the cell, and even larger losses in modules where parts of the cell are isolated. Furthermore, micro-cracking can lead to the formation of hot spots. If left unchecked, these problems can have considerable impacts on a site’s yield and therefore revenue. In other words, a prompt and thorough inspection is necessary to ensure that the system is operating properly despite the lack of obvious visible damage.

As with any response to a natural disaster, speed is key. Aerial inspection excels in this regard. Boasting rapid turnaround times, comprehensive inspection results, and flexible scheduling options, drone based aerial inspection methods give O&M providers the speed and adaptability necessary to quickly assess and repair damaged modules immediately following catastrophe.

The environmental aftermath of extreme weather and scale of the damage caused makes traditional field walk inspections nonviable. Flooding, fallen branches and other debris often make a site difficult to effectively traverse on foot, and field technicians typically only test a sample of 10-25% of a site’s modules when working under ideal conditions. Without the aid of aerial inspection, it is nearly impossible for field technicians to inspect an entire site in a reasonable amount of time. Other inspection methods such as fixed-wing aircraft inspectionallows for remote access to the site but to be scheduled weeks in advance, making it unsuitable for disaster response.

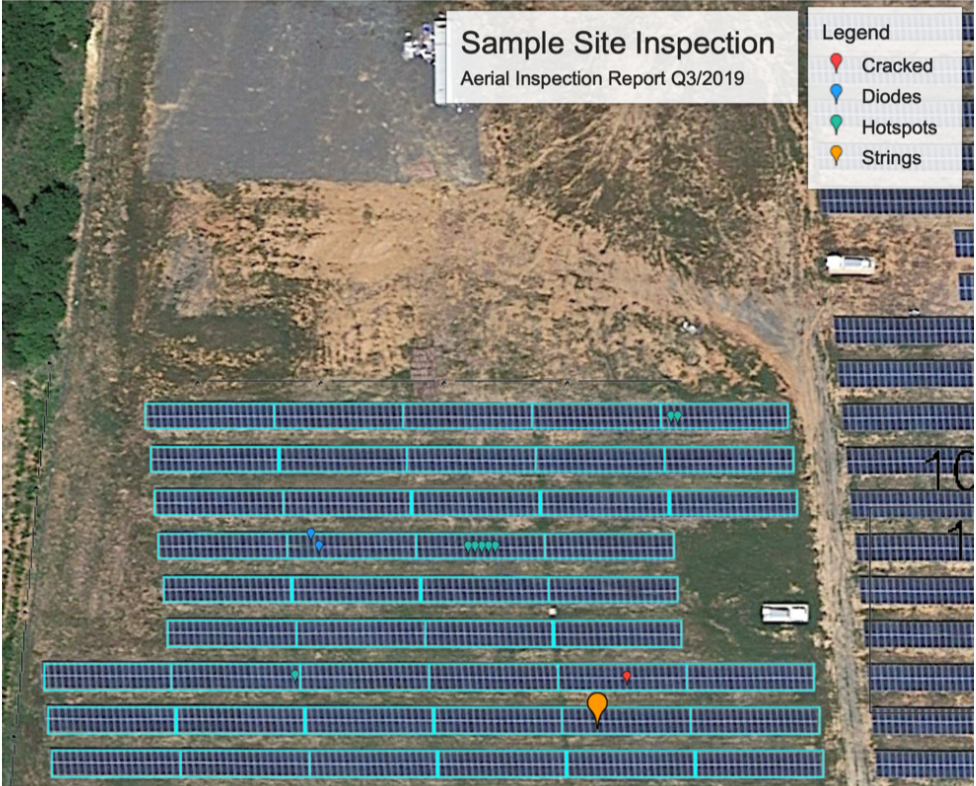

Aerial inspection presents a clean solution to these problems. Using a drone equipped with thermal imaging cameras, a complete and accurate inspection can be promptly conducted immediately following extreme weather. Debris, flooding, and other issues that prevent field technicians from accessing a site on foot have little to no effect on aerial inspection. As long as weather conditions are suitable, an inspection can be conducted as soon as the following day after a disaster. Aerial inspection is nearly 10x faster than traditional on-foot methods, allowing every individual module in the system to be inspected. This gives operators a more comprehensive overview of system performance and the total extent of any damage, all able to be reported within hours of inspection if necessary.

As we continue to observe patterns of increasingly extreme weather, likely as a result of climate change, O&M providers and asset managers will find themselves responding to damage caused by these events more frequently. In such instances — especially as solar becomes a more integral part of the global energy supply — a prompt and informed response is critical. Aerial inspection provides unparalleled speed and accuracy in the aftermath of disastrous weather that can be crucial in keeping PV systems operational.

If you are interested in how aerial inspection can be implemented into your disaster response plan, contact us at www.aerospec.us to learn more or schedule a demo today.

If you are interested in learning more about how aerial thermography can reduce labor costs and increase your yield, visit www.aerospec.us today for more information or to schedule a demo.