Introduction to Aerial Thermography

Aerial thermography is revolutionizing the way we think about solar operation and maintenance. Thermographic aerial inspection is the process of using a drone equipped with infrared sensors to inspect solar PV systems. Aerial inspection solutions providers, such as Aerospec Technologies, use the infrared images and/or videos captured during inspection in tandem with artificial intelligence to identify malfunctions that impact system performance. The following five-step process is an introduction to aerial thermography for solar PV systems.

How Does It Work?

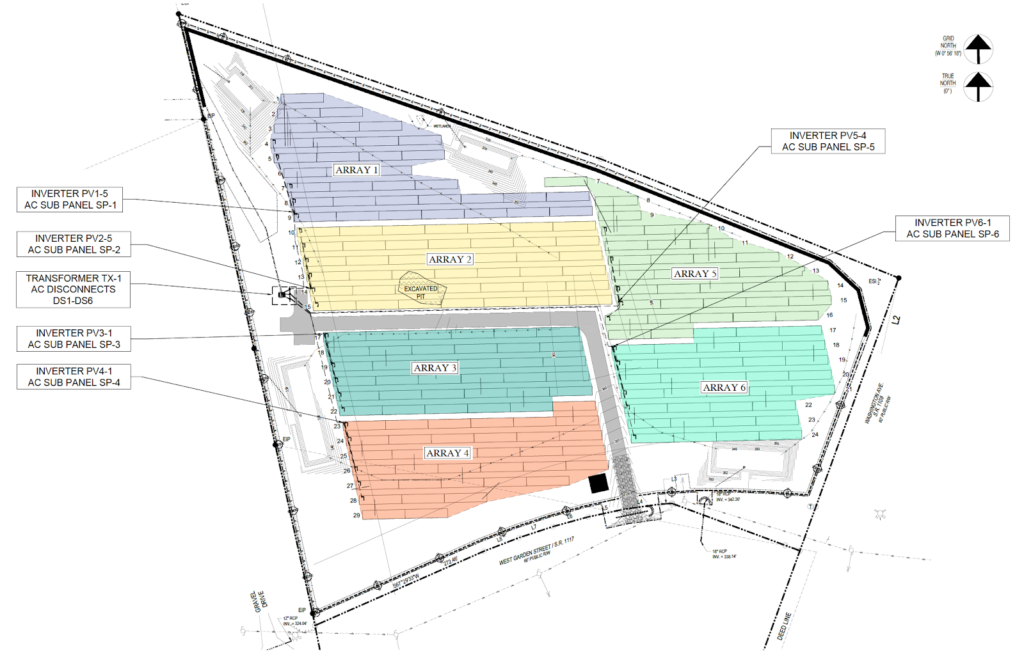

Prior to the first inspection, a digital map of the solar farm is created using an engineering as-built provided by clients (see Figure 1). This map provides relevant data including module manufacturer, models, and even serial numbers to Aerospec’s cloud platform. During the data acquisition phase, a drone equipped with a single thermal imaging sensor or dual RGB/IR sensors is used to capture inspection data. Data can be captured manually by a pilot or autonomously using Aerospec’s proprietary app designed specifically for solar farm inspection.

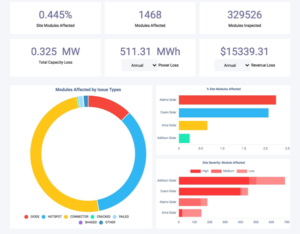

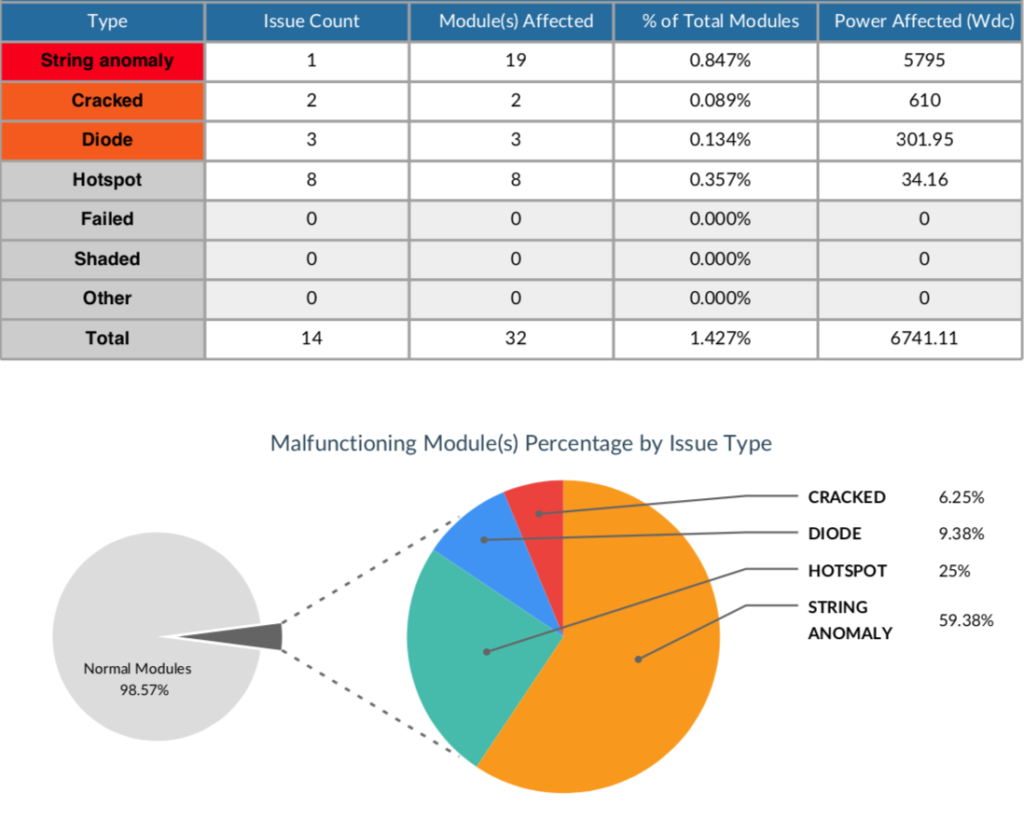

Once inspection data has been collected and uploaded to Aerospec’s cloud platform, it is analyzed using (our industry leading) artificial intelligence to detect anomalies that commonly impact site performance. Drawing on data from millions of previously inspected modules, the A.I. system can reach an accuracy close to 97%. A human quality assurance team ensures that all defects are properly identified and reported. The final report is delivered in PDF format complete with high quality visual aides. Additionally, Aerospec offers a number of downloadable alternative report formats, such as KMZ and CSV, allowing inspection data to be imported directly into Google Earth and Microsoft Excel, respectively.

Introduction to Benefits of Aerial Inspectionerial Thermography

The primary advantage of aerial thermographic inspection is its cost-effectiveness. Aerial inspections save solar farm owners and operators money because of their ability to survey a large number of solar modules quickly. Manual inspections are conducted on foot and often only sample a small section of modules. Aerial inspections are nearly 4x faster than manual inspection while improving accuracy. Technicians are able to rapidly detect and repair defective modules before they begin to severely impact yield, increasing site production, and saving on future operating and maintenance costs. According to a study published by Measure, by eliminating the tradeoff between accuracy and cost-effectiveness, solar farms save an average of $1,254 per MW after switching to aerial inspection. Furthermore, Aerospec Technologies is the industry leader in turnaround time, allowing for on-site remediation by technicians immediately/very shortly after each flight.

Conclusion

Aerial thermographic inspection is a valuable tool for solar PV owners and technicians. It permits fast and precise inspection, allowing technicians to quickly repair malfunctions and optimize a site’s performance, saving both time and money. Furthermore, when paired with a cloud platform such as Aerospec’s AeroSolar, easily accessible past inspection data and analytics provide maximum business intelligence across entire portfolios.

If you would like to learn more about how aerial thermography can optimize your portfolio, please contact us at www.aerospec.us for more information or to schedule a demo today.