The Return on Investment of Autonomous O&M

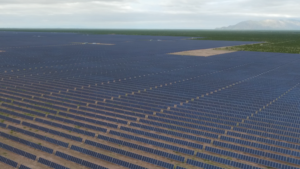

Mark Twain is rumored to have said, “Buy land, they’re not making it anymore.” This 19th century wisdom holds a measure of truth; land ownership is highly profitable in the long term. One of the more lucrative uses of land is solar energy production, due to increased demand for solar power within the past two decades. One of the key advantages in solar energy is the almost non-existent production cost.

Once a solar panel is erected, it will generate energy for free. After the initial investment, the only costs are O&M, or operations and maintenance. However, this can get fairly expensive. Repairing a broken component such as an inverter can cost tens of thousands of dollars, and failing to repair an issue could mean losing even more on a daily basis. As such, it is absolutely critical to regularly inspect farms and catch malfunctions as quickly as possible.

Until recently, the best way to do this was to hire crews with handheld thermal cameras and/or specialized instruments to inspect every module. For the typical 100MW solar farm that’s over 320,000 modules. Depending on the size of the farm, this process could take anywhere from several days to multiple weeks. A recent examination from Measure.com found that manual inspections took anywhere from about 10 hours per megawatt to 15 hours/MW, costing several hundred dollars an hour.

The National Renewable Energy Laboratory found that in 2010, the cost to each solar farm was was $28,000 per megawatt-year. Considering that these inspections must happen on a regular basis in order to catch malfunctions before they impede production, and operating for several years can become as expensive as constructing a farm in the first place.

There are, however, ways to drastically reduce that cost. Companies like Aerospec Technologies have developed software solutions that allows the process of inspection to be automated. By using drones, a single technician can inspect farms from a bird’s eye view in a fraction of the time it took entire crews on the ground. Where it took an inspection crew 778 hours to survey a 74MW farm, a drone service managed the same farm in 24 hours, saving $68,399. The reduced time is more or less standard across all sizes; while inspection crews require around 10 or more hours per megawatt, drone services can cover a megawatt in fifteen to twenty minutes. On average, drone services are cheaper than crews by $1,254/MW.

Additionally, since drones use monitoring software and AI-determined flight patterns, as well as multiple types of cameras, they are less prone to error than manual inspections and can spot defects earlier in the process. Establishing a working relationship with a Drone Service Provider gives both asset owners and Engineering, Procurement, and Construction Companies better control of the project. With constant flows of quantified data, they can efficiently assess whether the asset is meeting industry standards at any time.

Autonomous aerial inspections are more efficient for multiple stages of the process. Their benefits are clear for the operations phase, but drones have seen increased use by engineers for pre-construction land surveying and mechanical installation as well. Aerial Inspections for solar farms show a tremendous ROI both in short term savings, and long term continued efficacy of solar assets.

Aerospec provides you:

- Proven expertise in the renewable energy industry

- Reliable integration of hardware and software

- An AI-powered platform for advanced analytics

- Experts on board (FAA certified UAS pilots, solar researchers, certified thermographers)

- Safety-first mindset (zero incident record to-date)