Solar Power World estimates that a well maintained solar installation can perform 10 to 30% better than one that is not. However, it can be difficult to manage all of the assets, documents, and personnel necessary for the success of a maintenance team. Computer maintenance management systems (CMMSs) solve this problem by combining system data analysis, inventory management, and maintenance scheduling tools in one central system, helping technicians stay organized and enabling preventative maintenance. In this article, we will look at several popular CMMS solutions and discuss the potential benefits of integrating aerial inspection data with a CMMS platform so you can choose the one that’s right for your solar investment.

UpKeep

One of the most popular CMMS platforms available, UpKeep allows users to easily create and receive work orders, monitor asset performance, and schedule preventative maintenance routines. UpKeep utilizes cloud technology and a well designed mobile interface to keep maintenance teams up to date from anywhere.

UpKeep’s workflow automation system streamlines the creation of work orders. Using simple “if/then” statements, administrators can create automated workflow triggers that generate work orders for specific personnel and locations. For example, a workflow trigger is defined as “If a work order is created for Unit A, then assign work order to Team 1” will automatically assign all work orders created for Unit A to Team 1. UpKeep can also generate maintenance reports in PDF format and even create purchase orders.

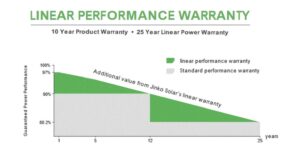

From year 2 through 25, the module should lose no more than 0.6% output annually, meaning that a module is guaranteed to output at least 83% of the labeled power output by the end of it’s 25 year warranty period. Most utility scale module manufacturers will offer a 25 year performance limited warranty guaranteeing roughly 80% performance through the end of the warranty period.

Power Factors Drive

Drive is a powerful CMMS designed specifically for renewable energy portfolios. Drive is able to ingest data from any original equipment manufacturer’s (OEM) SCADA system, normalizing time series data and then curating raw data to ensure accuracy.

In addition to the standard CMMS tools — work order, inventory management, and maintenance scheduling — Power Factors has developed a feature called Advanced Analytics in conjunction with the US Department of Energy. Advanced Analytics uses data from Drive to identify potential system or event-based causes for output loss. The integration of Advanced Analytics allows operations and maintenance providers to easily compare performance by site, account for weather based energy losses, and calculate soiling losses amongst, and much more.

Fiix

Like UpKeep and Drive, Fiix provides a robust cloud based platform that allows users to create work orders, manage inventories, and track asset performance. Featuring a customizable dashboard that displays user chosen key performance indicators, Fiix strives to make business intelligence available at a glance.

Fiix makes data collection and accessibility easy by allowing users to attach barcodes to assets and supplies. These barcodes, which are able to be scanned by any mobile device, can provide an asset’s maintenance history, common error codes, and more key information in seconds. Furthermore, Fiix features a customizable interface to reinforce internal processes while presenting information relevant to your team.

Some of Aerospec’s clients have stated that they preferred Fiix over other CMMS providers because of its superior design flexibility. Fiix makes up for what it lacks in industry specific design with its high level of customization.

Aerial Thermographic Integration

Proper implementation of CMMS tools facilitates maintenance routines that optimize a portfolio’s yield and therefore maximize the asset owner’s ROI. However, there is still room for innovation.

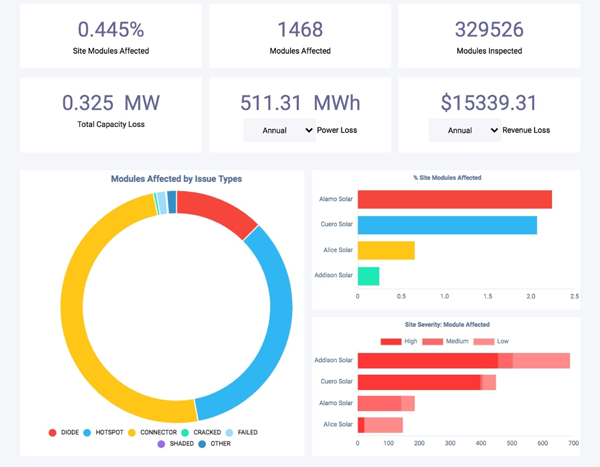

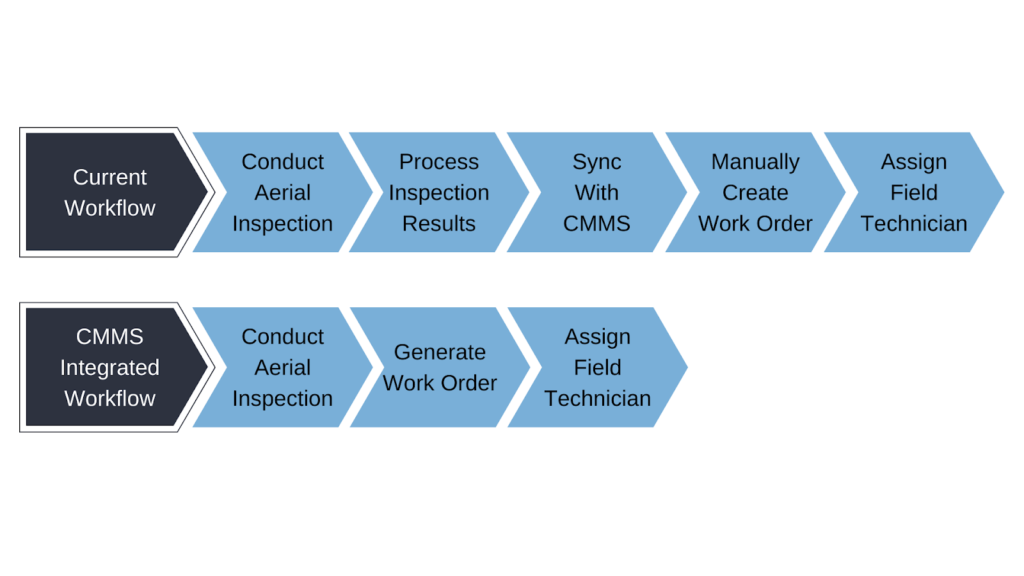

Aerial thermographic inspections use drones equipped with thermal imaging systems to quickly identify solar module anomalies such as diode bypasses, hotspots, and cracked panels. Currently, the data from these inspections is typically stored on the solution provider’s own platform. This requires technicians to use both the aerial solution provider’s platform as well as their CMMS to effectively monitor asset health and manually create workflows to further investigate those findings. Should CMMSs develop native support for aerial inspection data, solar module maintenance could become even easier and workflow process automation would become a reality.

If natively integrated into a CMMS, aerial inspection data could seamlessly provide relevant information on module malfunction type, manufacture information, location, and check against current inventory conditions for the specific module type. Automated work order tools found in most CMMSs could allow data from aerial thermographic inspections to automatically populate and assign work orders for modules suspected to be malfunctioning, so defective units could be repaired as they are discovered. Finally, integrating aerial inspection data into a CMMS would remove an extra step in the maintenance process and would give a more complete understanding of portfolio performance at a glance, ultimately helping O&M providers make informed decisions.

If you are interested in learning more about how aerial inspection can optimize your yield, visit www.aerospec.us today to learn more or schedule a demo.