Aerial inspection of solar assets offers many benefits compared to manual inspection. Using drones outfitted with thermal cameras, pilots are able to precisely and efficiently inspect large swathes of solar panels. The data gathered is then analyzed by an inspection solutions provider, which will identify current failures and predict future malfunctions. This process saves asset owners money by streamlining the inspection process and providing information that can be used to slash operating and maintenance costs when implemented proactively. However, there is one barrier to entry into aerial inspection: acquisition of the necessary hardware and professional personnel.

Currently, solar asset owners interested in aerial inspection have two options. They can either rent the services and hardware of a licensed commercial UAV pilot, or they can purchase their own drones and train technicians to operate them. While contracting pilots on a per inspection basis requires a smaller initial investment that makes sense for some asset owners, others, especially large utility-scale owners and operators with large solar portfolios, will often find that a CAPEX investment in an “in-house” team makes more financial sense.

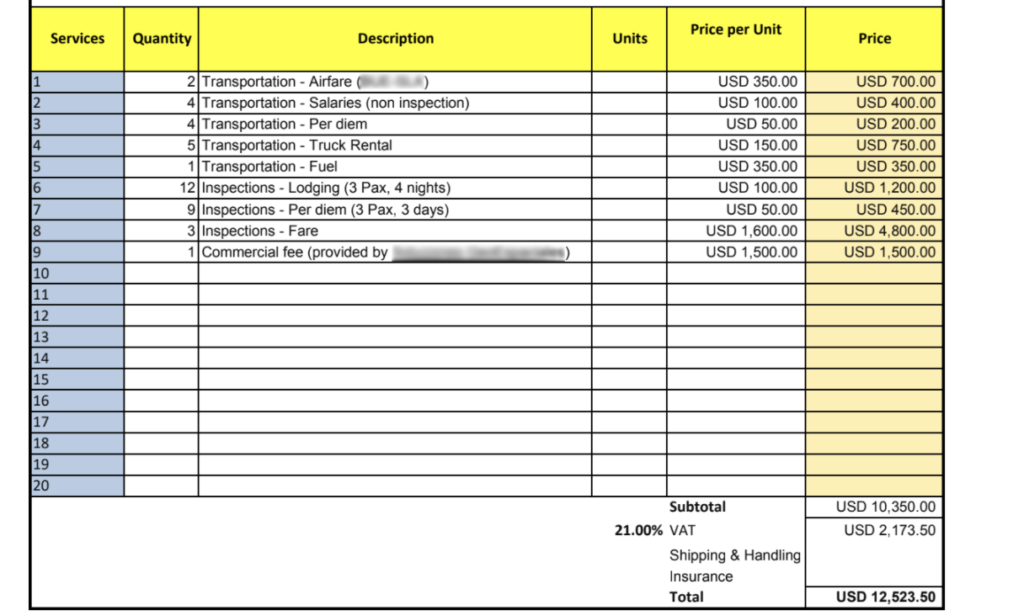

The cost of employing a third party drone pilot varies depending on the size and location of the solar farm as well as any extra expenses that may be necessary to accommodate for multiple day inspections in remote areas including food, lodging, and transportation. Pilot quotes obtained by Aerospec Technologies for inspections conducted in Argentina, Uruguay, Japan, and Australia had an average cost of $1,862 per day solely for the pilots’ services and hardware. A quote for a three day long inspection in Argentina totaled $12,523 after accounting for travel accommodations and a value-added tax (see Figure 2).

On the other hand, the initial investment to carry out the inspection in-house requires a considerable upfront cost and a technician’s time. The industry standard DJI Matrice 210 drone, equipped with the thermal camera Zenmuse Flir XT2 equipment, costs roughly $25,000. Furthermore, there are fees for obtaining a pilot license and any necessary training courses, depending on the country of operation. The Federal Aviation Administration in the United States charges $150 to take the aeronautical knowledge exam, which is required to obtain the FAA Part 107 Commercial Drone Operation License.

Asset owners with portfolios in several countries may find value in creating their own in-house inspection team in each country, rather than spending time and money on the logistics of sourcing the necessary equipment and personnel every time they would like to conduct an inspection. There are several logistical and legal challenges when attempting to perform aerial inspections across a portfolio spread over multiple countries. Renting the correct hardware and properly trained personnel locally is simply not possible in every part of the globe, leading some to import pilots and equipment from the United States. However, the US currently enforces export restrictions on many thermal infrared imaging camera systems necessary for data acquisition. To obtain a license to export the hardware, “the ultimate consignee or end user of the infrared product must furnish an end-use statement on company letterhead to ICI,” as well as a complete BIS-711 statement. These restrictions make sourcing hardware for international inspection from the US a lengthy process — 8-10 weeks on average depending on the completeness of the end statement and the verification of the user. Some countries also impose restrictions on who is allowed to operate a drone. In Mexico, for example, pilots are required to be Mexican citizens. After consulting with Aerospec’s drone services team, one of its large multinational clients implemented in-house inspection teams in multiple countries where the size of their portfolio is large enough to justify the cost. The client continues to employ third party pilot-for-hire services in countries where local regulations do not permit such a program.

Despite the high initial cost compared to renting a pilot’s services for several days, there is value in the flexibility of maintaining an internal drone team. For example, when employing a third party polit, if weather conditions don’t allow for an inspection, the contracted pilot still must be paid for their time. Commonly billed as an “idling charge,” the time spent unable to conduct an inspection is often recorded as an additional expense. This financial strain is compounded if it is necessary to provide travel accommodations for the pilot or if there was an import tax on the equipment. The formation of a dedicated inspection team can alleviate these costs. Florida Power & Light (FPL), which owns and operates more than 2,000MW of solar farms in the U.S., has a fully fledged in-house drone team equipped with multiple drone-in-a-box solutions that are available 24/7. Flexibility in planning and conducting inspections permits them to be conducted more frequently at a lower cost per inspection, allowing for maximum site performance and a higher yield over time. Should drone operation laws change so that a pilot-in-command is no longer required, inspections could even be conducted entirely autonomously on a regular schedule.

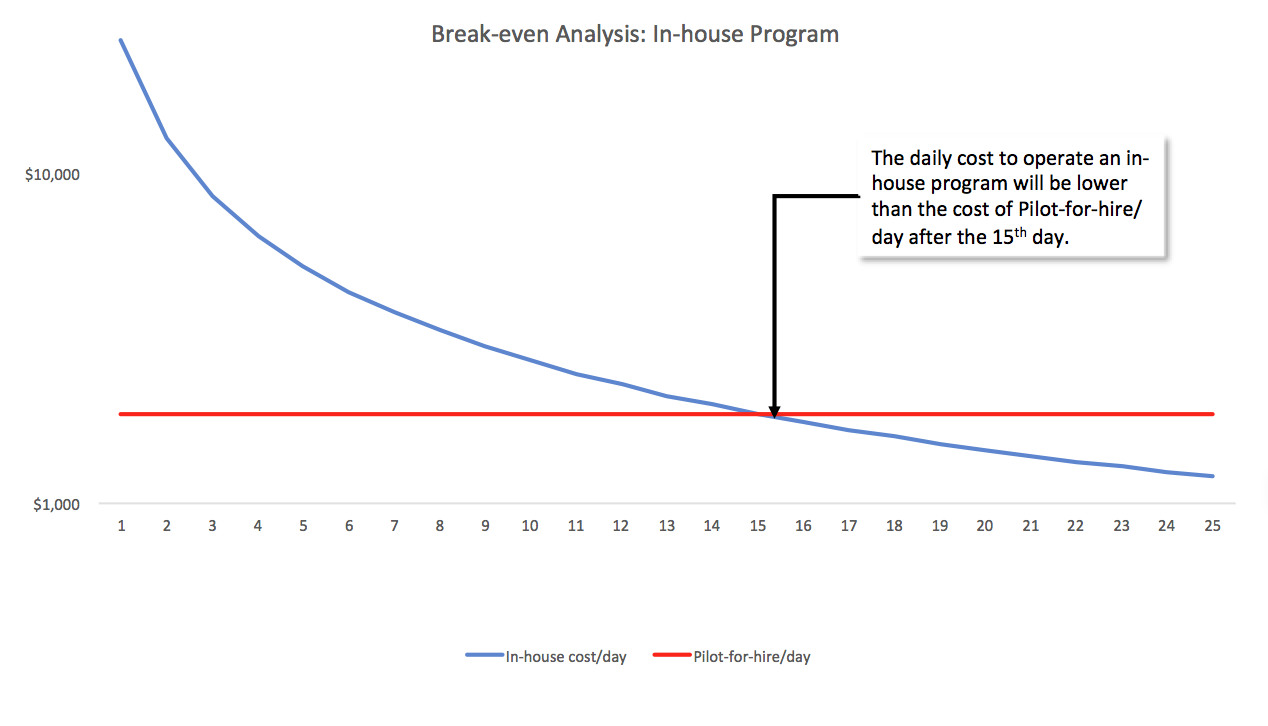

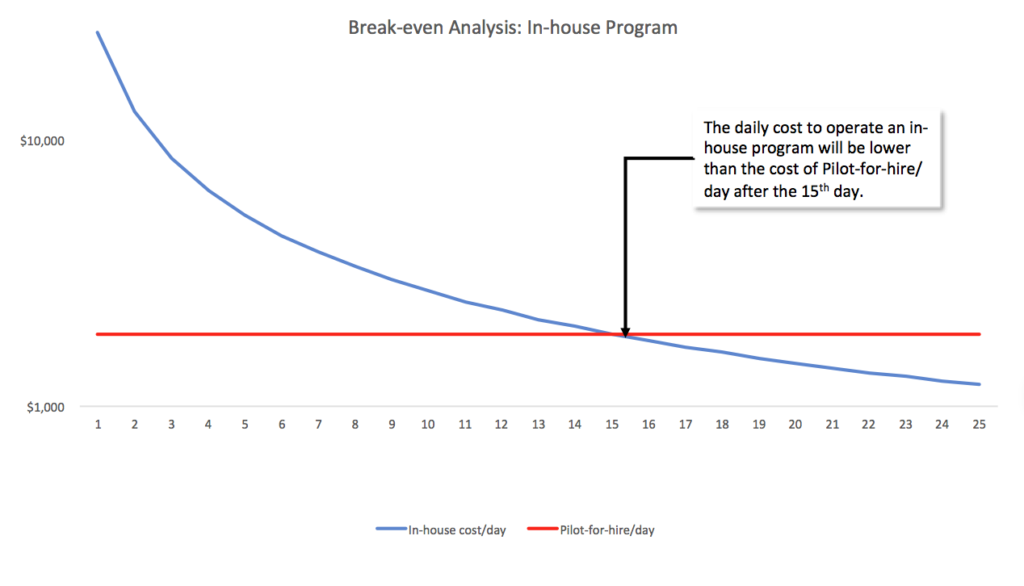

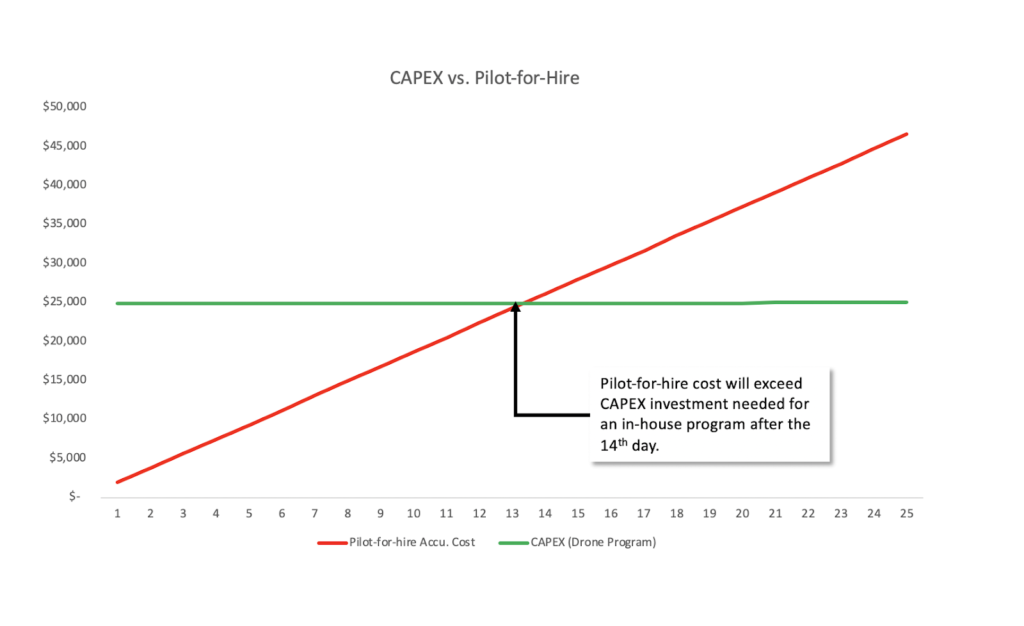

Solar asset owners looking to perform multiple inspections annually benefit from an in-house inspection team. Considering that pilot-for-hire services cost an average of $1,862 per day, the initial investment of $25,000 for a DJI Matrice 210 will be recouped after 14 days of in-house inspection (see Figures 3 and 4). Furthermore, assuming that a pilot can cover roughly 30MW per day of inspection, asset owners with a portfolio size of 402MW or more in a given country can recoup their investment in just one inspection of their portfolio.

Asset owners with smaller portfolios and low inspection frequencies may find that it is not worth the initial cost of investing in an in-house inspection team. On the other hand, those with large international portfolios will almost certainly find numerous benefits. Creating a dedicated inspection team on a per country basis negates the logistical and legal difficulties of conducting aerial inspections and allows for increased flexibility in maintaining one’s solar assets. The ROI for a hardware investment can be made after just 14 days’ worth of inspection while the ability to conduct multiple inspections annually at a lower rate will translate to additional profit as yield is consistently monitored and optimized. To further reduce the cost of setting up an internal drone team, Aerospec Technologies provides risk-free one day on-site training, ensuring that pilots have all the necessary knowledge to properly inspect a solar site.

To learn more about how aerial inspections can increase your solar asset yield or to inquire about Aerospec’s risk free on site training program, please visit our website.