Dr. Drew R. Michanowicz, a research fellow at the Center for Climate, Health and the Global Environment in the Harvard T.H. Chan School of Public Health, recently wrote an article in the Los Angeles Times discussing the problem of aging and unqualified pipeline infrastructure that led to the catastrophic Aliso Canyon gas leak in 2015.

One frequently overlooked cause of this disaster is the fact that the wells that use a single-pipe design in Aliso Canyon were not originally designed for high-pressure gas storage and did not have a backup safety valve to prevent blowouts.

“Out of the approximately 14,000 storage wells nationwide, about 2,700 might be Aliso-type wells,” Dr. Michanowicz wrote. At the end of the article, he appealed to the public and government to take action and prevent hazardous gas leaks in the energy industry.

Dr. Michanowicz cares deeply about environmental issues that significantly affect our society and believes applying technologies to solve the most challenging problems. In one of his recent research studies cooperatively conducted with Aerospec Technologies, Dr. Michanowicz estimated the advantages of using drone technology to perform air quality monitoring. Harnessing drones together with air quality sensors and data analytics enables environmental researchers to overcome two main challenges they meet when use traditional methods, which are 1) monitoring the air directly at source and in vertical plane, and 2) tracking the real-time 3-D pollution dispersion.

Beyond these two advantages of acquiring data directly and dynamically, it is a combination of drone technologies and data analytics that truly unleashes the potential of business intelligence in the inspection process. As a part of the workflow commonly known as “Robotic Process Automation” in the energy industry, an intelligent and automated inspection service will add measurable efficiency and values to the energy companies that are striving to decrease operational costs.

During the research study with Aerospec, Dr. Michanowicz also confirms the prospect of using drones and artificial intelligence in the O&M process for the energy industry. The energy industry includes infrastructure such as solar panels, wind turbines and gas pipelines that require regular manual inspection and maintenance work.

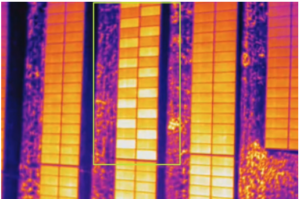

With high-resolution thermal data captured by drones, Aerospec’s current solution is able to identify and pinpoint malfunctioning assets based on precise geolocation, and also catalog and evaluate what type of and how serious each fault is — within hours and with minimal human supervision. This could be up to 10X faster than conventional manual methods.

To fundamentally prevent prolonged undetected outages and eliminate small defects from turning into big failures, Dr. Michanowicz emphasizes the necessity of substantial data acquisition and well-defined data interpretation, a specialty of Aerospec — accumulating more and more data to continually refine its machine learning algorithm and improve the accuracy of its data analysis.

Alongside sustainability advocates like Dr. Michanowicz, Aerospec will continue to collaborate with both academia and industry in the future, to contribute knowledge and techniques in aspects of drone, computer vision and machine learning into those ground-breaking researches.

To keep track of Aerospec’s development, follow us on LinkedIn or Facebook. Or request a demo to learn more about Aerospec’s technologies.